Inventory Management (MX01US03)

1. Problem Statement

Meter Supervisor (Device Manager)

- Cannot access real-time meter inventory data across multiple warehouses

- Spends excessive time locating specific meters for deployment or replacement

- Lacks a centralized system to track meter specifications, locations, and status

- Has difficulty monitoring inventory levels for procurement planning

- Cannot easily track the lifecycle of meters from acquisition to disposal

- Must maintain separate records for in-stock and disposed meters

- Struggles to generate accurate reports on meter inventory and lifecycle data

- Has limited visibility into meter performance history for evaluating manufacturers

Core Problem

The utility company lacks a centralized, digital meter inventory management system, resulting in operational inefficiencies, delayed service delivery, and potential procurement issues. The current fragmented approach using Excel files, physical registers, and direct communication creates information silos, inconsistent data, and time-consuming processes for accessing critical meter information.

2. Who Are the Users Facing the Problem?

Meter Supervisor (Device Manager)

Responsible for managing the utility's meter inventory and specifications, overseeing meter testing, calibration, and certification processes, and coordinating meter replacement programs. The Device Manager handles all aspects of meter lifecycle management from acquisition to disposal, ensuring appropriate inventory levels are maintained across warehouses and tracking the specifications and performance of different meter types.

3. Jobs To Be Done

For Meter Supervisor (Device Manager):

When I need to check current inventory levels across all warehouses, But I have to consult multiple Excel files or contact warehouse managers directly, Help me access a centralized inventory dashboard with real-time data, So that I can quickly determine meter availability and make informed procurement decisions.

When I need to locate meters with specific specifications, But I have to manually search through records at different locations, Help me filter and search the inventory database using multiple parameters, So that I can quickly find suitable meters for particular customer requirements.

When I need to track the lifecycle of meters from acquisition to disposal, But I have disconnected records across different systems, Help me access complete historical data for each meter in one place, So that I can analyze performance patterns and optimize replacement strategies.

When I need to manage the disposal of meters that have reached end-of-life, But I have to maintain separate records and manually update multiple systems, Help me digitally record and track disposal information with relevant details, So that I can maintain accurate records and analyze disposal patterns.

When I need to generate inventory reports for procurement planning, But I have to manually compile data from multiple sources, Help me create standardized reports with current and historical inventory data, So that I can efficiently plan purchases and optimize stock levels across warehouses.

4. Solution

Centralised Meter Inventory Management System

Inventory Tracking Capabilities

- Detailed meter records with device numbers, models, and specifications

- Location tracking with warehouse and storage position information

- Status indicators differentiating between available disposed meters

Search and Filter Functionality

- Advanced search options by Device number, model, type

- Multi-parameter filtering to find meters meeting specific requirements

- Export capabilities for inventory reports and data analysis

Meter Lifecycle Management

- Complete history tracking from acquisition to disposal

- Status change logging with timestamps

Integration Capabilities

- Work order system integration to assign meters

Bulk Operations

- Batch meter addition for efficient inventory updates

- Mass status updates for streamlined processing

- Group reporting for meter categories and types

Meter Specifications Library

- Detailed technical specifications for each meter model

5. Major Steps Involved

For Meter Supervisor (Device Manager):

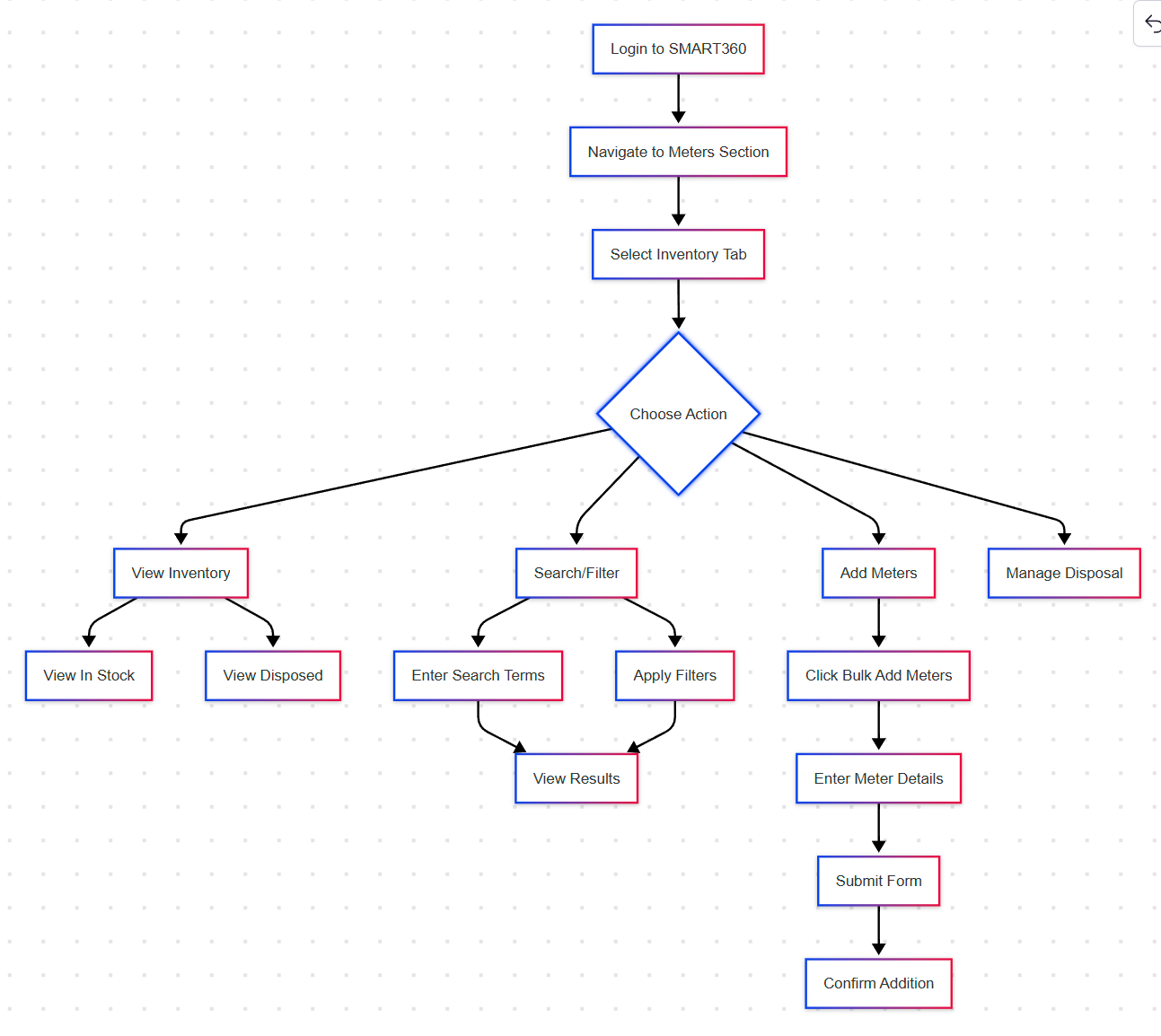

Accessing Inventory Overview

- Log into the SMART360 system

- Navigate to the "Meters" section from the main menu

- Select the "Inventory" tab to view the meter inventory management dashboard

- View summary metrics showing total meters available in stock (e.g., "5 meters available in stock")

- Toggle between "In Stock" and "Disposed" tabs to view different inventory categories

Searching for Specific Meters

- Use the search bar at the top of the inventory page

- Enter search criteria (serial number, model, or device number)

- View filtered results showing matching meters

- Alternatively, use the "Filters" button to access advanced filtering options

- Apply multiple filters based on type, manufacturer, location, etc.

- View the filtered inventory list showing only relevant meters

Adding New Meters to Inventory

- Click the "Bulk Add Meters" button in the top-right corner

- In the meter addition form, enter meter details including:

- Device numbers

- Type classification (SMART, PHOTO, MANUAL)

- Manufacturer (Dropdown form settings)

- Model (Dropdown form settings)

- Initial warehouse (Input field)

- Either enter information for multiple meters or upload a CSV file with batch data

- Type classification (SMART, PHOTO, MANUAL)

- Manufacturer (Dropdown form settings)

- Model (Dropdown form settings)

- Initial warehouse (Input field)

- The above information should be selected in both CSV and Manual entry cases

- Submit the form to add meters to the inventory

- Receive confirmation of successful addition with count of meters added

Reviewing Meter Specifications

- From the inventory list, click the specifications icon for a specific meter

- View detailed technical specifications including:

- Max Flow: 25 m³/s

- Accuracy: 99.5%

- Pressure Rating: 16 bar

- Manufacture Date: 2023-01-15

- Calibration Date: 2023-02-01

- Dail Length: 99mm

- Dail Count: 6

- Use this information to determine appropriate applications for different meter types

Generating Inventory Reports

6. Flow Diagram

7. Business Rules

General Inventory Rules

- Each meter must have a unique device number in the system

- Meters must be assigned to a specific warehouse location while in stock

- Meters cannot be in both "In Stock" and "Disposed" simultaneously

- Only users with appropriate permissions can add new meters to inventory

- Meters cannot be permanently deleted from the system, only marked as disposed

Meter Addition Rules

- Required fields for new meter addition include: Device Number, Model, Type, Make, Location

- Duplicate device numbers must be rejected with a clear error message

- Batch uploads must validate all records before processing any additions

- New meters must default to "Available" status

- Maximum batch size for bulk addition is 500 meters at once

Disposal Rules

- Disposed meters must have a disposal date, reason, and authorization record

- Valid disposal reasons include: Damaged, Decommissioned, Lost, Defective, End of Life

- Meters currently assigned to active work orders cannot be marked as disposed

- Currently installed meters must be removed from customer premises before disposal

- Disposal actions require supervisor-level authorization

- Disposal records must maintain last customer assignment information for reference

Search and Filter Rules

- Search must support partial matching of serial numbers and device numbers

- Filters must be combinable to create complex queries (e.g., type AND location)

- Search results must be sortable by any displayed column

- Maximum search results displayed per page is 50 items

- Search history must be preserved during the current session

Exporting Rules

- If any action is done like search, sort, filter and then clicked on export then the download should

- Consist of searched list items in case of search

- Filtered items in case of filter

- Sorted order in case of sort

Integration Rules

- Work order completion must automatically update meter status

- Installation: meter automatically moves to meter list form in stock list according to the device number attached in the installation service order, after approval of the service order.

- if disposed meter automatically moves to disposed tab

8. Sample Data

In Stock Meters

Serial/Device Number | Model | Type | Manufacturer | Location | Specifications |

|---|---|---|---|---|---|

SN-56789 (DM1234) | FlowMaster 3000 | SMART | Elster | Warehouse A | Flow rate: 0.5-25 gpm, Radio: 900MHz |

SN-67890 (DM2345) | AquaTrack 200 | PHOTO | Sensus | Warehouse B | Optical reading, Range: 0.1-15 gpm |

SN-78901 (DM3456) | WaterMetric Basic | MANUAL | Itron | Warehouse A | Mechanical register, Flow: 0.25-20 gpm |

SN-89012 (DM4567) | UltraFlow X5 | ULTRASONIC | Kamstrup | Field Office | Ultrasonic technology, Flow: 0.05-30 gpm |

SN-90123 (DM5678) | ReadyFlow AMR | AMR | Badger | Warehouse B | AMR compatible, Flow: 0.1-25 gpm |

Disposed Meters

Device Number | Model & Type | Manufacturer | Disposal Date | Reason | Lifespan | Last Consumer |

|---|---|---|---|---|---|---|

DM8765 | AquaTrack 100 (PHOTO) | Sensus | 2023-05-10 | DAMAGED | 5 years 7 months | Sarah Johnson |

DM6543 | UltraFlow X1 (ULTRASONIC) | Kamstrup | 2023-03-20 | DECOMMISSIONED | 7 years 9 months | Emma Wilson |

Meter Specifications

Model | Type | Flow Range | Battery Life | Communication | Accuracy | Compatible With |

|---|---|---|---|---|---|---|

FlowMaster 3000 | SMART | 0.5-25 gpm | 10 years | 900MHz radio | ±1.5% | AMI Network A |

AquaTrack 200 | PHOTO | 0.1-15 gpm | N/A | Optical | ±2% | Handheld Reader X |

WaterMetric Basic | MANUAL | 0.25-20 gpm | N/A | Visual | ±3% | N/A |

UltraFlow X5 | ULTRASONIC | 0.05-30 gpm | 15 years | RF 433MHz | ±0.5% | AMI Network B |

ReadyFlow AMR | AMR | 0.1-25 gpm | 12 years | AMR 900MHz | ±1% | Drive-by System Y |

9. Acceptance Criteria

- The system must display accurate count of in-stock meters on the inventory dashboard

- The system must categorize meters by status (In Stock, Disposed) with separate tab views

- The system must support search by device number, and model

- The system must provide filtering capabilities by type, manufacturer, and location

- The system must display complete meter details including specifications

- The system must support bulk addition of new meters through the interface

- The system must validate new meter information to prevent duplicates

- The system must capture and display disposal information including date, reason, and lifespan

- The system must calculate and display meter lifespan information for disposed meters

- The system must integrate with the work order system for meter assignments

- The system must prevent disposal of meters currently assigned to active work orders

- The system must provide exportable inventory reports

- The system must display meter-specific technical specifications

- The system must maintain searchable historical records of disposed meters

- The system must synchronize inventory data across all system modules

10. Process Changes

From | To | Impact |

|---|---|---|

Checking Excel files on individual computers for inventory information | Accessing centralized inventory dashboard with real-time data | Reduces information lookup time by 80% and eliminates version control issues |

Contacting warehouse managers directly to verify meter availability | Instantly viewing current inventory levels by location in the system | Decreases communication overhead and enables immediate decision-making |

Manually tracking meter assignments and installations in separate systems | Automated status updates as meters move through the workflow | Improves data accuracy and provides real-time visibility into meter location |

Paper-based or email disposal documentation | Digital disposal records linked directly to meter history | Creates complete audit trail and simplifies compliance reporting |

No centralized view of meter specifications | Comprehensive specifications library integrated with inventory | Enables faster selection of appropriate meters for specific applications |

Manual reconciliation of inventory across warehouses | Automated inventory balancing and transfer tracking | Optimizes inventory levels and reduces excess stock by 15-20% |

Limited visibility into meter lifecycles and performance | Data-driven lifecycle analytics by meter type and manufacturer | Improves procurement decisions and extends average meter lifespan |

Reactive procurement when stock runs low | Proactive inventory management with threshold alerts | Reduces emergency purchases and optimizes procurement costs |

11. Impact from Solving This Problem

Metric | Improvement |

|---|---|

Inventory management time | 75% reduction in time spent locating and verifying meter information |

Work order assignment efficiency | 60% faster assignment of appropriate meters to work orders |

Meter utilization rate | 15% improvement through better visibility and allocation |

Procurement planning accuracy | 25% more accurate forecasting of meter needs |

Inventory carrying costs | 12% reduction through optimized stock levels |

Meter installation delays | 40% fewer delays due to meter availability issues |

Regulatory compliance | 90% faster reporting for compliance requirements |

Staff productivity | 30% increase in tasks completed without adding resources |

Customer service response time | 50% faster response to customer inquiries about meter history |

Meter lifecycle optimization | 10% extension of average meter lifespan through better tracking |

12. User Behavior Tracking

Meter Supervisor (Device Manager) Tracking

Event | Properties | Metrics | Insights |

|---|---|---|---|

Inventory_Dashboard_View | User ID, Time spent, Tab selected (In Stock/Disposed) | Frequency, Duration, Tab preference | How often the Device Manager checks inventory status and which views are most valuable |

Meter_Search | Search terms, Filters used, Results count | Search patterns, Success rate | Which meter attributes are most frequently searched for and how to optimize the search experience |

Meter_Addition | Batch size, Success rate, Time to complete | Volume, Efficiency | Process efficiency for inventory updates and potential bottlenecks |

Meter_Disposal | Reason codes, Count, User | Disposal patterns, Reasons | Trends in meter failures and potential quality issues with specific models |

Report_Generation | Report type, Filters, Export format | Usage patterns | Which inventory insights are most valuable for decision-making |

Specification_View | Meter type, Specification category, Time spent | Usage patterns | How technical specifications influence inventory management |

Meter_Transfer | Origin/destination, Quantity, Purpose | Movement patterns | How meters flow between warehouses and potential optimization |

Filter_Usage | Filter combinations, Save frequency | Usage patterns | Which meter attributes are most important for inventory management |

Inventory_Export | Export format, Data selected, Frequency | Usage patterns | How exported data is being utilized for external processes |

Error_Encounter | Error type, Context, Resolution attempt | Frequency, Resolution time | What challenges are encountered during inventory management tasks |

Questions Answered Through Tracking

- Which meter types have the shortest lifespan and why?

- Which meter models experience the highest failure rates?

- How quickly can the Device Manager find information about specific meters?

- Are there patterns in meter disposal that suggest quality issues with specific manufacturers?

- How does meter lifecycle data influence procurement decisions?

- Which inventory management tasks consume the most staff time?

- Are inventory levels optimized across warehouse locations?

- How frequently are meters transferred between locations?

- Which search and filter combinations are most commonly used?

- How are technical specifications being utilized in inventory management?

- What is the efficiency of the bulk meter addition process?

- How effective is the disposal documentation process?

- Which report types provide the most value for inventory management?

- Are there seasonal patterns in meter inventory management activities?

- How does inventory management behavior change before and after procurement cycles?

No Comments