User Story: Manufacturers Management (AX04US01)

1. Problem Statement

This user story focuses on creating a centralized system to manage equipment and component manufacturers. The primary user for this feature is the Asset Manager, who is responsible for the lifecycle, performance, and strategic procurement of all utility assets.

Primary User Role & Pain Points:

- Asset Manager:

- Inability to Compare Performance: Lacks a simple way to track which manufacturers' assets are performing poorly or failing frequently, leading to suboptimal and costly procurement decisions.

- Disorganized Information: No centralized repository for manufacturer contact information, causing delays when needing technical support or ordering critical parts.

- Poor Risk Visibility: Cannot quickly assess the overall risk exposure associated with a single manufacturer's equipment across the entire utility, especially during a recall or systemic failure.

- Ineffective Strategic Planning: Lacks a clear, aggregated view of asset condition scores by manufacturer, which hinders the development of data-driven capital replacement plans.

- Manual Data Compilation: Spends excessive time and effort manually compiling data from disparate systems (asset registry, maintenance logs, procurement records) just to evaluate a single manufacturer's performance.

Core Problem:

For the Asset Manager, the lack of a centralized and integrated manufacturer management system results in inefficient procurement, poor strategic asset planning, and increased operational risk. They cannot easily track manufacturer performance, manage supplier information, or assess the impact of a single manufacturer on the utility's overall asset health, leading to higher long-term costs and potential service disruptions.

2. Who Is the User Facing the Problem?

While several roles like the Utility Administrator and Meter Manager will use this feature, the Asset Manager is the most important user. Their core responsibility is to make high-value, long-term decisions about the utility's physical infrastructure. This feature directly provides the strategic insights they need to perform their job effectively.

Access Control:

The Asset Manager should have full create, read, update, and deactivate permissions for this feature. Other roles like the Utility Administrator will also have full access, while roles like O&M Manager and Meter Manager will have read-only access.

3. Jobs To Be Done

- For the Asset Manager: When I need to make strategic procurement and replacement decisions, but I cannot easily compare the real-world performance, failure rates, and condition of assets from different manufacturers, help me by providing a centralized dashboard that aggregates asset data by manufacturer, so that I can invest in reliable equipment, reduce long-term operational costs, and proactively manage asset risk.

4. Solution

The proposed solution is a comprehensive Manufacturers Management module integrated within the SMART360 platform, designed primarily for the Asset Manager. This module will serve as the central, authoritative source for all information related to equipment and component manufacturers, providing the tools needed to track, analyze, and manage these critical suppliers from a strategic perspective.

Key Capability Areas:

- Centralized Manufacturer Directory: A searchable and filterable list of all manufacturers.

- At-a-Glance Dashboard Analytics: High-level KPI cards summarizing key metrics like total active manufacturers, manufacturers of critical assets, and those with high failure rates.

- Detailed Manufacturer Profile: A comprehensive view for each manufacturer, including contact details, product categories, and notes.

- Integrated Asset & Inventory View: A tabbed interface within the manufacturer profile to list all associated assets and inventory items.

- Performance & Health Score Aggregation: The manufacturer profile displays key aggregated metrics:

Total Assets,Total Inventory items, andAverage Asset Condition Score. - Structured Data Entry & Management: A validated modal form for adding and editing manufacturer details to ensure data quality.

- Seamless Navigation & Actions: Clickable links and clear navigation to move between the list and detailed profiles, with quick actions to edit or deactivate.

5. Major Steps Involved

User Role: Asset Manager

Flow 1: Adding a New Manufacturer

Flow 2: Reviewing a Manufacturer's Performance for Strategic Planning

6. Flow Diagram

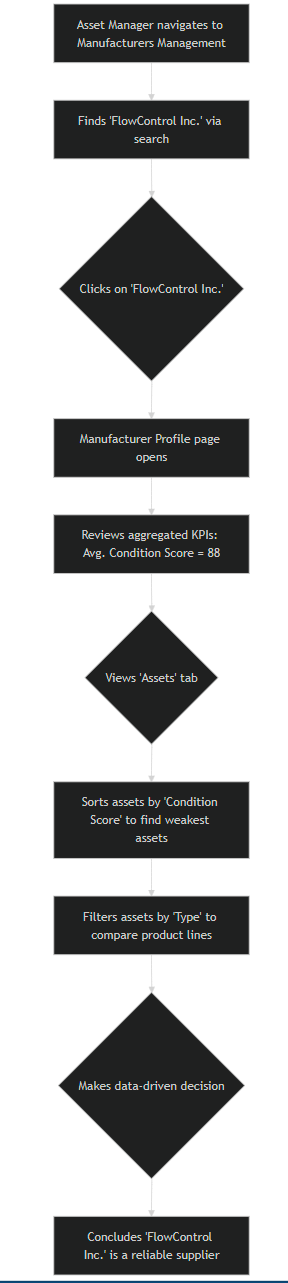

Flow: Asset Manager Reviews Manufacturer for Strategic Decision

7. Business Rules

This section provides a detailed breakdown of rules for every visible element on the screen.

A. Manufacturers Management (Main List View)

- Page Title ("Manufacturers Management"): Static text.

- Page Subtitle ("Manage comprehensive list..."): Static descriptive text.

- Button: "+ Add New Manufacturer":

- Visible only to users with create/edit permissions (e.g., Asset Manager, Utility Admin).

- Clicking this button must open the "Add New Manufacturer" modal.

- KPI Card: "Total Manufacturers"

- Title: Static text.

- Value (e.g., 3): This is a calculated field. Formula:

COUNT(Manufacturers)whereStatus= 'Active'. It must update in real-time if a manufacturer's status changes or a new active one is added. - Subtitle ("Active manufacturers"): Static text.

- KPI Card: "Manufacturers with Critical Assets"

- Title: Static text.

- Value (e.g., 2): This is a calculated field. Formula:

COUNT(DISTINCT ManufacturerID)for manufacturers linked to at least one asset where theAsset.IsCriticalflag is TRUE. - Subtitle ("15+ asset types"): This appears to be descriptive text. If dynamic, it would be

COUNT(DISTINCT Asset.Type)for assets linked to these manufacturers.

- KPI Card: "Manufacturers with High Failure Rates"

- Title: Static text.

- Value (e.g., 0): This is a calculated field. Formula:

COUNT(Manufacturers)who are in the Top 5 for failure rates. The Top 5 list is determined by ranking manufacturers by theCOUNT(WorkOrders)whereWorkOrder.Type= 'Failure' or 'Repair' over the last 12 months. - Subtitle ("Top 5 tracked"): Static text indicating the scope of the metric.

- KPI Card: "New Manufacturers (Last 1 Year)"

- Title: Static text.

- Value (e.g., 0): This is a calculated field. Formula:

COUNT(Manufacturers)whereCreationDateis within the last 365 days from the current date. - Subtitle ("Recently added"): Static text.

- Search Bar ("Search manufacturers..."):

- Must filter the main list table in real-time as the user types.

- The search should apply to the

Manufacturer IDandManufacturer Namefields.

- Filter: "All Status":

- A dropdown that filters the table.

- Options must include "All Status", "Active", and "Inactive".

- Default value is "All Status".

- Filter: "All Countries":

- A dropdown that filters the table.

- The list of countries must be dynamically populated from the

Countryfield of all manufacturers in the database. - Default value is "All Countries".

- Button: "Export":

- Must export the currently displayed (and filtered) list of manufacturers.

- The export format should be CSV or XLSX.

- Table Column: "Manufacturer ID": Displays the unique, system-generated ID (e.g., MFG-001).

- Table Column: "Manufacturer Name": Displays the official name of the manufacturer.

- Table Column: "Primary Contact": Displays the name of the main contact person.

- Table Column: "Contact Email": Displays the email of the main contact person.

- Table Column: "Phone Number": Displays the primary phone number for the manufacturer.

- Table Column: "Website": Displays the manufacturer's website URL.

- Table Column: "Country": Displays the country where the manufacturer is based.

- Table Column: "Status":

- Displays the current status as a visual tag.

- "Active" must have a green background.

- "Inactive" must have a gray or muted background.

- Table Column: "Assets Produced":

- This is a calculated field for each row. Formula:

COUNT(Assets)whereAsset.ManufacturerIDmatches the manufacturer in that row.

- This is a calculated field for each row. Formula:

- Table Column: "Actions":

- Represented by a "..." (kebab) icon.

- Clicking it must open a dropdown menu with options like "View Profile", "Edit", and "Deactivate/Activate".

- Pagination Controls ("Previous", "1", "2", "Next"):

- Must be present if the total number of records exceeds the page size (e.g., 10 rows).

- The controls must correctly navigate through the pages of the manufacturer list.

B. Add New Manufacturer (Modal View)

- Modal Title ("Add New Manufacturer"): Static text.

- Section Title ("Basic Manufacturer Information"): Static text.

- Field: "Manufacturer Name":

- This is a mandatory text input field.

- The system must show an error if the user tries to save without filling this.

- Uniqueness Rule: The system must validate that the combination of

Manufacturer NameandCountryis not already in use.

- Field: "Status":

- A dropdown with options "Active" and "Inactive".

- The default value must be "Active".

- Section Title ("Contact Information"): Static text.

- Field: "Primary Contact Person": Optional text input field.

- Field: "Contact Email":

- This is a mandatory text input field.

- Validation Rule: The input must be a valid email format (e.g.,

user@example.com).

- Field: "Phone Number": Optional text input field.

- Field: "Website":

- Optional text input field.

- Validation Rule: If a value is entered, it must be a valid URL format.

- Field: "Country":

- A dropdown list of all countries.

- This is an optional field.

- Section Title ("Product Categories & Notes"): Static text.

- Field: "Product Categories":

- A multi-select dropdown.

- The list of categories must be predefined and managed by a Utility Administrator to ensure consistency.

- Field: "Notes": An optional, multi-line text area for additional information.

- Button: "Cancel": Must close the modal without saving any changes.

- Button: "Save Manufacturer":

- Must trigger validation on all fields.

- On successful validation, it saves the new manufacturer record to the database, closes the modal, and refreshes the main list.

C. Manufacturer Profile (Detail View)

8. Sample Data

Manufacturer List Data:

Manufacturer ID | Manufacturer Name | Primary Contact | Contact Email | Phone Number | Website | Country | Status | Assets Produced |

|---|---|---|---|---|---|---|---|---|

MFG-001 | FlowControl Inc. | John Smith | +1-555-0123 | United States | Active | 15 | ||

MFG-002 | AquaPump Solutions | Sarah Johnson | +1-555-0456 | Canada | Active | 8 | ||

MFG-003 | HydroTech Systems | Michael Brown | +1-555-0789 | United States | Active | 22 | ||

MFG-004 | EuroValve GmbH | Hans Mueller | +49-30-12345678 | Germany | Inactive | 5 |

Manufacturer Profile Data (for FlowControl Inc.):

- Assets Tab:

| Asset ID | Asset Name | Asset Type | Location | Status | Condition Score | Risk Score | Last PM Date |

| :--- | :--- | :--- | :--- | :--- | :--- | :--- | :--- |

| VALV-005 | Main Line Gate Valve | Valve | Main Depot, WH1 | Operational | 85 | 63 | 2025-06-01 |

| PUMP-012 | Centrifugal Water Pump | Pump | Station A | Under Maintenance | 72 | 78 | 2025-05-15 | - Inventory Items Tab:

| Item ID | Item Name | Category | Stock On Hand | Unit Cost | Last Ordered Date |

| :--- | :--- | :--- | :--- | :--- | :--- |

| GASK-015 | Gasket (6-inch Flange) | Gaskets & Seals | 50 | $15.00 | 2025-06-10 |

| VALV-PART-001 | Valve Seat Ring | Valve Components | 25 | $45.00 | 2025-05-28 |

9. Acceptance Criteria

- The system must allow a user with appropriate permissions to add a new manufacturer.

- The system must generate a unique, sequential

Manufacturer IDfor each new manufacturer. - The system must require

Manufacturer NameandContact Emailwhen adding a new manufacturer. - The system must validate that the

Contact EmailandWebsitefields are in the correct format. - The system must display a list of all manufacturers in a table with all columns as specified in the screenshot.

- The system must allow users to search the manufacturer list by name and ID.

- The system must allow users to filter the manufacturer list by

StatusandCountry. - The system must provide an option to

Exportthe filtered manufacturer list to a CSV file. - The system must navigate to a detailed profile page when a user clicks on a manufacturer row.

- The system must display all the manufacturer's profile information and make the email and website clickable links.

- The system must display the correct calculated values for

Total Assets,Total Inventory items, andAverage Asset Condition Scoreon the profile page. - The system must provide "Quick Actions" to

Edit Manufacturer,Deactivate, andContact Manufacturer. - The system must display a list of all associated assets under an "Assets" tab on the profile page.

- The system must display a list of all associated inventory items under an "Inventory Items" tab on the profile page.

- The system must allow searching and filtering within the "Assets" and "Inventory Items" lists on the profile page.

- The system must prevent a user from deleting a manufacturer. Deactivation should be the only removal option.

- The system must correctly calculate and display the four KPI cards on the main management page based on their defined formulas.

- The system must update the

Assets Producedcount in the main list whenever an asset is associated with that manufacturer. - The system must render the "Active" and "Inactive" status tags with distinct colors (green and gray).

- The system must provide a confirmation prompt before a user deactivates a manufacturer.

10. Process Changes

From: (Current Process) | To: (New Process) | Impact Analysis |

|---|---|---|

Manufacturer data is stored in disparate spreadsheets and is often out of date or inconsistent. | All manufacturer data is stored and managed in a single, centralized module within SMART360. | Justification: Centralization eliminates data redundancy and ensures a single source of truth. This will reduce time spent searching for information and correcting data errors. |

Evaluating manufacturer performance requires manually compiling data from asset, maintenance, and finance systems. | The Manufacturer Profile automatically aggregates asset count, inventory levels, and average condition scores. | Justification: Automating this analysis saves the Asset Manager significant time. A task that took 4-6 hours of manual data compilation can now be done in minutes, an efficiency gain of over 90% for this specific task. |

Contacting a manufacturer requires searching for contact details in old emails, files, or external systems. | Contact information (email, phone) is readily available and clickable directly from the manufacturer's profile. | Justification: This reduces the time to initiate contact from several minutes to a few seconds, speeding up procurement and incident response processes. |

Onboarding a new supplier is an unstructured process with a high risk of missing key information. | A guided, validated form ensures all critical information is captured consistently for every new manufacturer. | Justification: This improves data quality from the point of entry, reducing downstream issues caused by incomplete or inaccurate data. |

Identifying all assets from a specific manufacturer during a recall is a time-consuming manual search across the asset registry. | The "Assets" tab on the manufacturer profile instantly lists all associated assets. | Justification: This reduces the time for impact analysis from hours or days to seconds, enabling a much faster and more effective response to safety recalls or systemic failures. |

11. Impact from Solving This Problem

Metric | How it Improves |

|---|---|

:white_check_mark: Strategic Procurement Decisions | By providing clear, data-driven insights into asset performance and condition scores by manufacturer, the Asset Manager can make better long-term purchasing decisions, favoring reliable suppliers and reducing total cost of ownership. |

:white_check_mark: Operational Efficiency | Centralizing information reduces time spent by staff searching for manufacturer details, managing data, and compiling reports. This frees up time for more value-added activities like analysis and strategic planning. |

:white_check_mark: Reduced Operational Risk | The ability to quickly identify all assets from a single manufacturer is critical for responding to recalls or widespread equipment failures, minimizing potential service disruptions and safety incidents. |

:white_check_mark: Improved Supplier Relationship Management | Having a single source of truth for contacts, performance, and history allows for more effective communication and management of supplier relationships. |

:white_check_mark: Enhanced Data Integrity | Moving from spreadsheets to a structured system with validation rules drastically improves the accuracy and consistency of manufacturer data across the utility. |

12. User Behavior Tracking

Primary User Role: Asset Manager

Metric/Event Name | Event Trigger | Properties Tracked | Question Answered for the Asset Manager |

|---|---|---|---|

View Manufacturer Dashboard | Asset Manager lands on the main Manufacturers Management page. |

| How frequently is the Asset Manager reviewing the overall manufacturer landscape? |

Add New Manufacturer | Asset Manager successfully saves a new manufacturer. |

| Is the Asset Manager expanding the supplier base with new vendors? |

View Manufacturer Profile | Asset Manager clicks on a manufacturer to view their detailed profile. |

| Which manufacturers are being investigated most often? Are they typically high-performing or low-performing suppliers? |

Export Manufacturer List | Asset Manager clicks the "Export" button. |

| Is the Asset Manager performing offline analysis, and on which subset of manufacturers? |

Sort Assets on Profile | Asset Manager sorts the asset list on a profile page. |

| Is the Asset Manager using performance metrics like Condition Score to evaluate a manufacturer's product line? |

Filter Asset List on Profile | Asset Manager applies a filter on the "Assets" tab. |

| Is the Asset Manager drilling down into specific asset types to compare performance within a manufacturer's portfolio? |

No Comments