Master : User Story Docuement (WX01US01)

1. Problem Statement

Utilities face significant challenges in maintaining consistent field service operations across various service types, assets, and technician teams. This leads to:

- Inconsistent Service Delivery: Without standardized procedures, field technicians perform similar tasks with varying methods and quality.

- Safety Compliance Risks: Utility operations involve numerous safety hazards that require consistent adherence to protocols.

- Inefficient Resource Allocation: Without proper task planning and resource requirements, field operations face delays and cost overruns.

- Poor SLA Management: Service Level Agreements are difficult to track and maintain without structured procedure templates.

Lack of Knowledge Standardization: Critical operational knowledge remains siloed within experienced technicians rather than being captured in accessible formats.

Core Problem: The organization lacks a centralized, standardized system for creating, managing, and enforcing Standard Operating Procedures (SOPs) for field service operations across different utility types, resulting in inconsistent service quality, safety risks, and inefficient resource utilization.

2. Who Are the Users Facing the Problem?

Based on the provided screenshots and user personas document, the following key user roles are involved in the SOP management and service order processes:

1. UtilityIT/System AdministratorAdministrators

Responsible for overallthe technical setup and configuration of the platform. They ensure the system configurationis properly tailored to the utility's specific needs and businessmaintain processthe implementation.technical Creates and manages master templatesinfrastructure that alignsupports withwork utilityorder business processes.operations.

2. O&MOperations ManagerManagers

OverseesOversee maintenancethe overall work order process and operationaccess ofthe utilitymaster distributionpage systems.to Responsibleensure alignment with operational goals and standards. They are responsible for ensuringthe consistentefficiency and effectiveness of field operations throughacross standardizedthe procedures and managing overall service quality.utility.

3. DispatcherSupervisors/Managers

CoordinatesAccess the master page to manage and configure work order templates, assign roles, and ensure efficient workflow management. They handle day-to-day supervision of work order processes and field operations by assigning work to appropriate technicians. Manages scheduling, prioritization, and resource allocation to meet service level agreements.teams.

4. Field Force Technician

Executes maintenance, installation, and repair work by following standardized procedures in the field. Primary end-user of SOPs during service delivery.

5. System Admin

Oversees the technical implementation and access control for the SOP management system.

3. Jobs To Be Done

For UtilityIT/System Administrator:

When I need to implementconfigure standardizedand fieldmaintain servicethe procedures,work order management system, But I struggle with inconsistenttechnical protocolscomplexities and integration requirements across departmentsutility and service types,operations, Help me createimplement anda managestandardized comprehensivetemplate SOP templatessystem with built-inproper bestrole-based practices,access controls, So that I can ensure operationalsystem consistencyreliability, data integrity, and regulatoryseamless complianceworkflow across the utility.departments.

For O&MOperations Manager:

When I need to oversee maintenancework andorder repair operationsprocesses across utility systems,operations, But I face challenges with varyinginconsistent workprocedures, unpredictable service quality, safetyand SLA compliance, and resource utilization, Help me establish and enforce standardized procedureswork order templates with appropriatebuilt-in safetyperformance protocolsmetrics and performance metrics,visibility, So that I can improve serviceoperational reliability,efficiency, reduceensure safetyregulatory incidents by 30%,compliance, and optimize operationalresource efficiency.utilization.

For Dispatcher:Supervisor/Manager:

When I need to efficientlymanage assignday-to-day work order assignments and coordinateteam field service work,performance, But I struggle with matchingbalancing theworkloads, righttracking technicians to jobsprogress, and meetingensuring serviceprocedure level agreements,adherence, Help me quickly identify appropriate SOPs andefficiently assign themstandardized work orders based on technician skills and location,prioritize activities, So that I can maximizemeet service level agreements, improve first-time resolution rates, meet SLA targets, and optimizemaintain fieldservice workforce utilization.quality.

For Field Force Technician:

When I need to perform installation or maintenance tasks in the field, But I lack clear guidance on proper procedures and safety requirements, Help me access detailed, step-by-step instructions with safety protocols and equipment lists, So that I can complete tasks correctly, safely, and within estimated timeframes.

For System Admin:

When I need to configure and maintain the SOP management system, But I must ensure proper access controls and system integration, Help me establish role-based permissions and monitor SOP usage metrics, So that I can optimize the system's performance and support operational efficiency.

4. Solution

The SMART360 SOP Management System provides a comprehensive platform for creating, managing, and deploying standardized operating procedures across utility operations. The solution addresses the key pain points through these capabilities:

1. Centralized SOP Repository

- Template Library: Pre-configured templates for common utility procedures (meter installation, leak inspection, pressure checks)

- Version Control: Track changes and maintain historical versions of SOPs

- Search & Filter: Easily find relevant SOPs by

utilitysoptype,idservice&category,templateor equipment typename

2. Standardized Template Builder

- Multi-step Wizard Interface: Guided creation process with logical flow (Basic Info → Safety Requirements → Task Definition → Materials & Equipment → Readings → Help → Review)

- Utility Type Classification: Categorize SOPs by utility (Water, Gas, Electricity) for appropriate requirements

- Service Association Mapping: Link SOPs to specific service types and asset categories

3. Comprehensive Safety Management

- Safety Requirement Packages: Pre-configured safety protocols (Confined Space, Electrical Safety, Working at Heights)

- Safety Protocol Selection: Choose from standard safety protocols based on task requirements

- PPE Requirements: Define specific personal protective equipment needed for each procedure

4. Task Definition Framework

- Standardized Task Templates: Pre-built task templates for common field activities

- Time Estimation: Set expected completion times for planning and performance tracking

Mandatory Task Flagging: Identify critical tasks that cannot be skipped during execution

5. Materials & Equipment Management

- Material Packages: Define standard material kits for specific procedures

- Equipment Requirements: Specify tools and testing equipment needed for each SOP

- Quantity Management: Track required quantities for inventory and resource planning

6. Measurement & Readings Framework

- Reading Sets:

Configure standardpredefined sets of measurements to be collected during procedure execution Acceptable Ranges: Define normal operating parameters for validating field readingsCritical Threshold Alerts: Flag readings that indicate potential safety or operational issues

7. Knowledge Base Integration

- Support Resources: Attach documentation, videos, and references to SOPs

- Field Feedback Loop: Collect technician feedback on SOP effectiveness and clarity

- Template Rating System: Enable quality assessment of SOP templates

8. Workflow & Approval Process

- Draft Management: Save works-in-progress for further refinement

- Review & Approval: Structured review process before SOP publication

Publication Controls: Manage when and how SOPs become available to field teams

9. Analytics & Insights

- SOP Performance Tracking: Monitor completion times against estimated durations

- Usage Metrics: Track which SOPs are most frequently used and by whom

- SLA Compliance: Measure service delivery against defined SLA targets

10. Integration Capabilities

Field Service Application Integration: Push SOPs to mobile devices for field executionAsset Management Linkage: Connect SOPs to specific asset types and categoriesWork Order System Connection: Associate SOPs with work orders and service requests

5. Major Steps Involved

For

The Utilityfollowing Administrator:

Accessrepresents the end-to-end process flow for SOPManagementmanagementDashboardand execution in the SMART360 system:1. SOP Template Creation

Navigate toAccess the Master section intheSMART360navigation menuView SOP overview metrics (Total SOPs, Active SOPs, Template Types, Avg SLA)

Create New SOP Template- Click "Create SOP" button

onto launch theMaster dashboard System displays the multi-stepSOP Builder wizard

- Click "Create SOP" button

DefineComplete the BasicSOPInfoInformationEnter SOP Namesection (e.g.,name,"Waterdescription,MeterutilityInstallation")Providetype,shortservicenameassociation,forSLAquick referenceWrite description explaining the purpose and scopeparameters)- Select

UtilityappropriateTypeSafety(Water,RequirementsGas, Electricity, HVAC, or Other) Choose Service Association from dropdown listSelect Typepackages andSubtype categoriesprotocols- Define

SLArequiredinTaskshours/days Specifywithestimated labor cost, tax rate,descriptions andrequiredtimefieldforce count

Configure Safety RequirementsSelect from pre-configured safety packages based on procedure risksChoose applicable safety protocols for the specific procedureSpecify required PPE items for the field technicians

Define Task StructureSelect from task templates or create custom tasksDefine task names, descriptions, and estimated completion timesMark mandatory tasks that cannot be skippedConfigure task dependencies and sequence

- Specify Materials & Equipment

Add material packages containing required parts and suppliesSpecify field inspection toolsneeded for the procedureDefineConfigurequantitiesrequiredforReadingseachandmaterialmeasurementitemparameters- Add

equipmentHelpfrom a pre-configured or custom equipment list

Configure Required ReadingsSelect reading sets appropriate for the procedureDefine acceptable parameter ranges for each readingSet threshold values for alertsresources andescalations

Add Help ResourcesUpload supporting documentation or instructionsAdd contact information for subject matter expertsInclude field feedback functionality for continuous improvement

- Review

& PublishPreviewthe complete SOPtemplateCheck all sections for completenessandaccuracySavepublish or save asDraft or Publish as Standard templateSet effective date for the new proceduredraft

For2. SOP Review

- O&M

Manager:SearchManagerforreviewsRelevant SOPsNavigate to Master sectionFilter SOPs by utility type, service category, or statusUse search function to find procedure by name or ID

Review SOP DetailsSelect SOP from the list to view detailsReview task definitions, safety requirements, and resource needsCheck SLA and estimated completion time

Approvedraft SOPs forField OperationsReview and validate SOPs align withoperationalstandardsvalidityEnsureVerify safety requirements meetdepartmentregulatoryguidelinesstandardsConfirmValidateresourcetaskrequirements are accurately specified

Monitor SOP PerformanceTrack actual completion times against estimated durationsReview any exceptions or deviations reported by field techniciansAnalyze SLA compliance across different procedure typesIdentify opportunities for procedure optimization

For Dispatcher:Access Work Management SystemLog into the dispatcher console in SMART360View incoming service requestssequences andwork orders

Select Appropriate SOPIdentify the service need and required procedureSearch for and select the matching SOP templateReview SOP requirements and resource needs

Assign Work to Field TechniciansMatch technician skills to SOP requirementsCheck technician availability and locationAssign SOP-based work order to selected technicianPrioritize assignments based on SLA requirements

Coordinate Field ResourcesEnsure required equipment and materials are availableCommunicate special instructions to assigned techniciansSchedule work according to SOPtime estimatesAdjustConfirmassignmentsmaterial and equipment lists are complete- Check reading parameters for appropriate thresholds

4. Field Execution

- Technician reviews assigned SOP on mobile device

- Verify safety requirements and confirm proper equipment

- Follow task sequence as

fielddefinedconditionsinchange

MonitorCompleteWork ProgressTrack real-time status of assigned SOPsRespond to technician requests for assistanceReassign work as needed to meet SLA targetsUpdate customers on service timing based on SOP progress

For Field Force Technician:Receive Work Assignment with SOPAccess assigned work orders through Field Force mobile applicationView attached SOP details and requirementsAcknowledge receipt of assignment

Review Safety RequirementsCheck requiredmandatory safety protocolsand PPEConfirm understanding of safety proceduresVerify availability of all required safety equipmentComplete required safety checksbefore beginning work

Execute Tasks According to SOPFollow step-by-step task instructions in sequenceCheck off completed tasks in the mobile application- Record required readings and measurements

Follow standardized procedures for eachDocument task completion with timestampsUseCapturereferenceanymaterialsdeviationsattachedortoexceptionsthefromSOPstandard procedure- Take photos of completed work as

neededrequired

5. Completion and Documentation

- Technician marks all required tasks as complete

DocumentSystemCompletion- validates all mandatory tasks and readings are completed

- Record actual time spent

oncomparedeach task Document any deviations from standard procedureCapture photos or additional notes as requiredProvide feedback onto SOPclarity or improvement opportunitiesestimates- Document material usage and equipment

usage

SubmitObtainCompletedcustomerWorkVerifyacknowledgmentallifmandatory tasks are completedrequired- Submit

finalcompleteddocumentationSOP to system - Dispatcher reviews completion status and

readingscloses service order

6. Performance Analysis

- Calculates estimated completion time

Complete any required customer sign-offsReportIdentify SOPcompletioncompliancetoratedispatcherand exceptionsFlagTrackanySLAissuesperformancerequiringacrossfollow-updifferentworkSOP types- Analyze reading data for operational insights

- Identify opportunities for SOP optimization

- Review feedback submitted by field technicians

- Publish revised SOP version with improvement notes

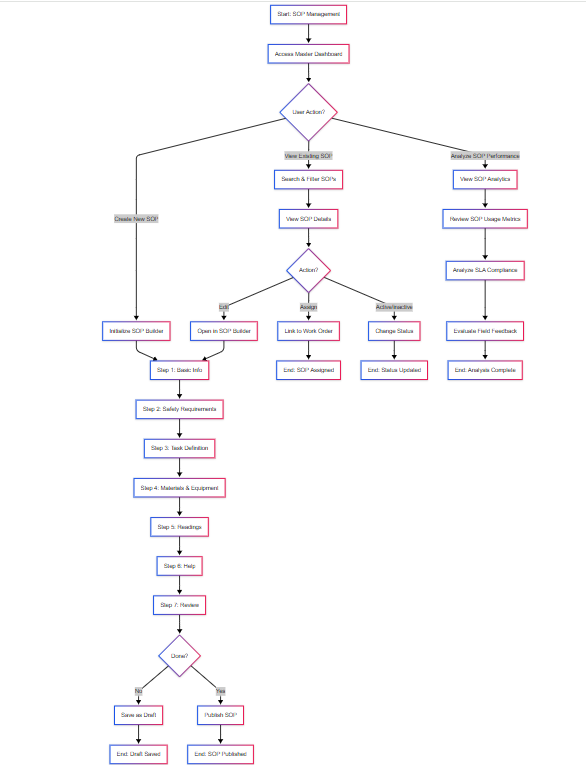

6. Flow Diagram

flowchart TD

A[Start: SOP Management]Link --> B[Access Master Dashboard]

B --> C{User Action?}

C -->|Create New SOP| D[Initialize SOP Builder]

C -->|View Existing SOP| E[Search https://www.mermaidchart.com/raw/06d814c5-3914-404c-84c5-85987900df5e?theme=light& Filter SOPs]

C -->|Analyze SOP Performance| F[View SOP Analytics]

D --> D1[Step 1: Basic Info]

D1 --> D2[Step 2: Safety Requirements]

D2 --> D3[Step 3: Task Definition]

D3 --> D4[Step 4: Materials version=v0.1& Equipment]

D4 --> D5[Step 5: Readings]

D5 --> D6[Step 6: Help]

D6 --> D7[Step 7: Review]

D7 --> D8{Approve?}

D8 -->|No| D9[Save as Draft]

D8 -->|Yes| D10[Publish SOP]

E --> E1[View SOP Details]

E1 --> E2{Action?}

E2 -->|Edit| E3[Open in SOP Builder]

E2 -->|Assign| E4[Link to Work Order]

E2 -->|Archive| E5[Change Status]

F --> F1[Review SOP Usage Metrics]

F1 --> F2[Analyze SLA Compliance]

F2 --> F3[Evaluate Field Feedback]

D9 --> G[End: Draft Saved]

D10 --> H[End: SOP Published]

E3 --> D1

E4 --> I[End: SOP Assigned]

E5 --> J[End: Status Updated]

F3 --> K[End: Analysis Complete]

7. Business Rules

General SOP Management Rules

- Each SOP must be associated with exactly one utility type (Water, Electricity, Gas, HVAC, or Other)

- SOPs must have a unique identifier (SOP-XXX) assigned by the system upon creation

- All SOPs must include at least one task in the task definition section

- SLA must be defined in hours or days for each SOP

- Active SOPs cannot be deleted but can be archived if no longer needed

- SOP templates can only be published after all mandatory fields are completed

DraftworkSOPsinareprogessonlysop'svisiblecantobecreatorssavedandinadministrators until publisheddraft

Safety Requirement Rules

- SOPs must have at least one safety protocol selected if the procedure involves field work

- Hazardous procedures must include specific safety packages appropriate to the risks involved

- PPE requirements must be explicitly defined for each SOP

Safety protocols with regulatory requirements cannot be removed from applicable SOPsConfined space procedures must include Emergency Response Plan protocol

Task Definition Rules

- Tasks must have estimated completion times for proper resource planning

Critical operational tasks must be marked as mandatoryTasks with dependencies must be clearly identified in the sequence- Each SOP must have a maximum allowed completion time for SLA tracking

- Task templates can be reused across multiple SOPs

Materials & Equipment Rules

- All specialized tools required for a procedure must be listed in the equipment section

- Material quantities must be specified for inventory planning

Critical equipment must be clearly identified for prioritizationStandard material packages can be defined and reused across multiple SOPsEquipment with calibration requirements must include last calibration date verification

Readings & Measurements Rules

Acceptable parameter ranges must be defined for all required readingsCritical readings must have alert thresholds configured- Reading units must be standardized and clearly displayed

Reading verification steps must be included for safety-critical measurementsHistorical reading comparisons must be available for trend analysis

User Access Rules

Only Utility Administrators and System Admins can create and publish SOP templatesO&M Managers can view and assign SOPs but not modify published templatesField Force Technicians can only view assigned SOPs and submit completion dataSOP editing is restricted to the original creator or authorized administratorsDraft templates are only visible to the creator and system administrators

SLA & Performance Rules

- SOP completion time is calculated from assignment to final task completion

- SLA

exceptions must be documented with reason codes SLAperformance is tracked

Calculation andavg reportedsla

- Avg

atSLAindividualper SOP:and36category levelshours - Exemption

rateRate:cannot exceed defined threshold5% (currently↓ 5%)

To calculate the average SLA (Service Level Agreement) time per SOP performance(Standard metricsOperating areProcedure), calculatedyou dailyneed and visibledata on the Mastertime dashboardtaken for each SOP case. The general formula is:

Average SLA Time = (Sum of SLA Times for All SOPs) / (Total Number of SOPs)

Example:

If you had the following SOP completion times (in hours):

- SOP 1: 30h

- SOP 2: 36h

- SOP 3: 42h

Then:

Average SLA = (30 + 36 + 42) / 3 = 108 / 3 = 36 hours

The 5% exemption rate implies that 5% of SOPs were excluded from SLA calculations (e.g., due to valid exceptions or issues outside control), so you'd calculate the average only using the remaining 95% of SOPs.

8. Sample Data

SOP Templates

Required Fieldforce Count |

Preventive Maintenance |

Safety Requirements

PPE |

Insulated Gloves, Safety Glasses, Hard |

Respirator, Safety Harness, Gas |

Safety Harness, Hard Hat, Safety |

Chemical Resistant Gloves, Face Shield, Protective Suit |

Task Templates

Material Packages

Reading Sets

Utility Reading SetParametersNormalSets

Reading RangeAlertSet

Reading ThresholdStandardName

Unit

Expected Range

Criticality

Photo Required

Standard Utility MeterInitialMeter Reading,Readings

Current FinalMeter ReadingN/AN/APressureReading

kWh

0 SystemStaticto Pressure,10000

Medium

No

Peak Demand Reading

kW

0 to 100

Medium

No

Power Factor

-

0.8 to 1.0

Medium

No

Pressure System Readings

System Pressure

PSI

30 to 80

High

Yes

Differential Pressure40-60Pressure

PSI

2 PSI,to 1-10

High

Yes

Electrical System Readings

Voltage Reading

V

110 to 130

High

No

Current Draw

A

5 PSI<to 30 PSI, >8 PSIElectrical SystemLoad Current, Voltage,

Medium

No

Insulation Resistance5-30A,Resistance

MΩ

1.0 115-125V,to >1MΩ>35A, <110V or >130V, <0.5MΩ100

High

No

Water QualityTurbidity,Quality pH,Readings

pH Level

pH

6.5 to 8.5

Medium

No

Chlorine Level<1

mg/L

0.2 NTU,to 6.5-8.5, 0.2-4mg/L>5 NTU, <6.4.0 or >9.0, <

Medium

No

Turbidity

NTU

0.1 orto >4.5mg/L1.0

Medium

No

Gas System Readings

Gas Pressure

kPa

1.0 to 3.0

High

No

Flow Rate

m³/h

0.5 to 10.0

Medium

No

Gas Meter Reading

m³

0 to 100000

Low

No

9. Acceptance Criteria

- The system must allow creation of SOP templates for multiple utility types (Water, Gas, Electricity, HVAC, Other)

- The system must enforce unique SOP IDs for all templates in the format SOP-XXX

- The SOP Builder must guide users through a 7-step creation process: Basic Info, Safety Requirements, Task Definition, Materials & Equipment, Readings, Help, and Review

- Users must be able to save drafts at any point in the creation process

- The system must support selection of pre-configured safety packages and individual safety protocols

- The SOP Builder must allow creation of task sequences with time estimates and dependency relationships with predefnied packages

- Tasks must be able to be flagged as mandatory

or optional - The system must support material and equipment package definition with quantity specifications

- Reading requirements must include parameter ranges

and alert thresholds - The system must calculate and display SLA metrics for all active SOPs

- The

SOPmaster dashboardpage must display key metrics: Total SOPs, Active SOPs, Template Types, and Avg SLA - Users must be able to filter SOPs by utility type, priority, and status

- The system must track usage count for each SOP template

- Field feedback mechanisms must be available for continuous improvement

- The system must support attachment of reference materials and help documentation

- Users must be able to define required fieldforce count for resource planning

- Published SOPs must be visible to all authorized users based on role permissions

- The system must support draft, active, and archived status for SOP lifecycle management

- The system must validate that all required fields are completed before publication

- The system must provide a comprehensive review screen showing all SOP components before final publication

10. Process Changes

Current ProcessNewProcess New ProcessImpactProcess Impact AnalysisFieldAnalysis Field procedures vary between technicians and locationsStandardizedlocations

Standardized SOPs ensure consistent execution regardless of technician or location40%location

Significant reduction in procedure variation, leadingresulting toin more predictable service quality and betteran improved customer experienceSafetyexperience

Safety protocols are often verbally communicated or found in separate manualsIntegratedmanuals

Integrated safety requirements directly within each SOP60%SOP

Marked improvement in compliance with safety protocolprotocols compliance;and 30%a reductionnoticeable decline in safety incidentsMaterialincidents

Material and equipment needs determined by individual techniciansStandardizedtechnicians

Standardized material packages and equipment lists defined for each procedure25% reduction inprocedure

Fewer return trips due to missing equipment;equipment 15%and reduction inreduced excess inventoryCompletioninventory

Completion time varies significantly between techniciansSLAstechnicians

SLAs defined and tracked for each procedure type35%type

Greater improvementconsistency in schedule adherence;adherence, Bettersupporting improved capacity planning and workforce utilizationKnowledgeutilization

Knowledge transfer relies on shadowing experienced techniciansDetailedtechnicians

Detailed procedures captured in digital format with supporting resources50% reduction inresources

Faster training time for new technicians;technicians Criticaland better retention of knowledge retainedwithin despitethe workforce turnoverFieldorganization

Field issues addressed through ad-hoc escalationStructuredescalation

Structured protocols for readings outside acceptable ranges45% fasterranges

Quicker resolution of abnormal conditions;conditions Moreand more consistent customercommunication communicationwith customers during service issuesProceduredisruptions

Procedure improvements implemented inconsistentlyCentralizedinconsistently

Centralized template management with version control70%control

Faster fasterand more consistent rollout of procedure improvements; Better complianceupdates, with improved alignment to regulatory changesLimitedrequirements

Limited visibility into field service performanceComprehensiveperformance

Comprehensive analytics on SOP usage and completion metrics80%metrics

Enhanced improvementvisibility ininto performanceperformance, visibility;enabling Data-more informed, data-driven decisions for process optimizationdecision-making

11. Impact from Solving This Problem

Metric Before Improvement Service Consistency

MetricImprovementService

Service Consistency40%quality varied widely due to inconsistent procedures

Significant reduction in variation of service quality variationdue to standardized procedures

Field Technician Productivity

Daily output varied depending on technician experience and process familiarity

Noticeable increase in task completion through standardized proceduresFieldand Technicianoptimized Productivity25%workflows

First-time Resolution Rate

Frequent second visits required due to missing tools, materials, or unclear procedures

Marked improvement in tasksresolving completedissues peron daythe throughfirst standardized, optimized proceduresFirst-time Resolution Rate30% increase in first-time fixesvisit by ensuringequipping technicians havewith properthe procedures,right tools, and materialsSafetyresources

Safety Incident Rate35%Rate

Safety reductionprotocols were often informal or inconsistently followed

Clear decrease in safety incidents through integrated safety protocols and PPEprotective requirementsSLAequipment Compliance45%requirements

SLA Compliance

SLAs were often missed due to unclear expectations and inconsistent execution

Strong improvement in meeting service level agreementstimelines through clearly defined procedures

Training Efficiency

New technicians required extended shadowing and timeinformal expectationsTraining Efficiency50% reduction in technicianlearning

Faster onboarding timethrough byaccess providingto clear,standardized, standardizedeasy-to-follow proceduresKnowledgeprocedures

Knowledge Retention90%Retention

Operational preservationknowledge was lost with workforce turnover

High level of critical operational knowledge despitepreserved workforcethrough turnoverRegulatorythorough Compliance60%procedural improvementdocumentation

Regulatory inCompliance

Audit preparation was reactive and documentation was incomplete

Better audit readiness withthrough documented procedurescomprehensive and accessible safety protocolsCustomerand Satisfaction25%process increasedocumentation

Customer inSatisfaction

Customer satisfactionexperiences scoreswere throughinconsistent moreand delays were common

Noticeable improvement due to consistent, timelytimely, and professional service deliveryOperationaldelivery

Operational Cost15%Cost

High reductioncosts from inefficiencies, rework, and redundant resource usage

Reduction in overall field service costs through optimized resource utilizationallocation and reducedfewer reworkrepeat visits

12. User Behavior Tracking

For UtilityIT/System Administrator

Event Properties Metrics Insights System_Configuration_Updated

EventPropertiesMetricsInsightsSOP_Creation_Startedutility_type,

config_area, user_id, timestampCreationtimestamp

Configuration frequency, abandonmentsystem rateAreareas administrators actively developing new procedures? modified

Which utilityconfiguration types need more standardization?SOP_Publishedsop_id, creation_duration, utility_typeTime to create, templates by categoryHow efficiently are SOPs being created? Are certain utilities receiving more focus?SOP_Template_Editedsop_id, sections_modified, reason_codeEdit frequency, common modificationsWhich sectionsareas require the most refinement?attention? How often are changes needed?

User_Role_Modified

role_id, permission_changes, affected_users

Permission adjustments, access patterns

Are role definitions effective? Which permissions are most frequently adjusted?

Integration_Performance_Checked

integration_point, response_time, error_rate

System performance, integration reliability

Which integration points are causing issues? Are SOPsthere stablerecurring orperformance frequentlyproblems?

System_Report_Generated

report_type, changing?Safety_Package_Addedpackage_type,parameters, sop_id,execution_time

Reporting utility_typeSafetyusage, coveragesystem byresource procedureutilization

Which typeArereports safetyare requirementsmost beingvaluable? appropriatelyAre integratedthere intoperformance allissues procedurewith types?complex reports?

For O&MOperations Manager

EventPropertiesMetricsInsightsSOP_Reviewedsop_id,EventPropertiesMetricsInsightsTemplate_Performance_Viewedtemplate_id, review_duration,performance_metrics, sections_viewedReview patterns, focus areasAre managers thoroughly reviewing SOPs before approval? Which aspects receive most scrutiny?SOP_Performance_Viewedsop_id, user_id, filter_appliedAnalysistime_periodAnalysis frequency, focus areasAreareasWhich managersperformance activelyaspects monitoringare SOPmost performance?monitored? Are template designs achieving efficiency goals?SLA_Compliance_Reviewedservice_type, compliance_rate, exception_countCompliance patterns, problem areasWhich service types have SLA challenges? What factors affect compliance rates?Resource_Utilization_Analyzedresource_type, utilization_rate, cost_metricEfficiency analysis, cost optimizationAre resources properly allocated? Which service areas have utilization issues?Work_Order_Volume_Analyzedwork_type, geographic_area, trend_dataWorkload distribution, trend analysisAre there patterns in service demand? How effectively is work distributed?

For Supervisor/Manager

EventPropertiesMetricsInsightsWork_Order_Assignedwork_order_id, technician_id, priority, estimated_timeAssignment patterns, workload distributionHow balanced are work assignments? Are high-priority items appropriately staffed?Technician_Performance_Reviewedtechnician_id, metrics_viewed, time_periodPerformance management, focus areasWhat aspects of technician performance receive mostattention? attention?SLA_Exception_Reviewedsop_id,How exception_reason,does action_takenExceptionfeedback patterns,translate resolutionto actionsWhatimprovement?Template_Modifiedtemplate_id, modification_type, reason_codeTemplate refinement, improvement areasWhich templates require adjustment? Are modifications improving efficiency?Schedule_Adjustedoriginal_timing, new_timing, reason_codeSchedule adherence, adjustment patternsWhat causes SLAschedule breaches?changes? How effectively are exceptionsadjustments addressed?SOP_Feedback_Reviewedfeedback_id, sop_id, action_takenFeedback utilization, improvement cycleIs field feedback being incorporated into procedure improvements?

For Dispatcher

EventPropertiesMetricsInsightsSOP_Assignedsop_id, work_order_id, technician_id, priorityAssignment frequency, distribution patternsWhich SOPs are most frequently used? Are assignments properly balanced across the workforce?SOP_Searchsearch_terms, filters_applied, selected_sopSearch efficiency, selection patternsHow efficiently are dispatchers finding appropriate SOPs? Are search terms aligned with SOP naming?Technician_Selectiontechnician_id, sop_id, selection_criteriaMatch quality, skill utilizationAre dispatchers matching technicians to SOPs based on skills and experience?SLA_Monitoringsop_id, time_to_deadline, action_takenProactive management, escalation patternsAre dispatchers actively managing SLA compliance? What actions prevent SLA breaches?Assignment_Adjustmentoriginal_assignment, new_assignment, reasonReassignment frequency, adjustment reasonsWhat triggers work reassignment? How efficiently are field resources reallocated?handled?

For Field Force Technician

EventPropertiesMetricsInsightsSOP_Viewedsop_id,EventPropertiesMetricsInsightsWork_Order_Viewedwork_order_id, technician_id,view_duration, duration, sections_viewedUsagesections_accessedUsage patterns, referenceinformation frequencyHow often do technicians reference SOPs? WhichneedsWhich sections of work orders require most review? Is information clearly presented?Task_Completedtask_id, sop_id, actual_duration, sequence_numberCompletion timeefficiency, vs. estimate, sequenceprocess adherenceAre tasktime estimates accurate? Do technicians follow the prescribed sequence?Reading_Recordedreading_type,Field_Data_Recordeddata_type, value,completion_time, threshold_statusReadingexception_flagData collection efficiency, quality issuesIs field data collection efficient? Which data points cause collection problems?Work_Order_Feedback_Submittedwork_order_id, feedback_type, improvement_suggestionFeedback patterns, alert frequencyHow often do readings fall outside normal ranges? Are thresholds appropriately set?SOP_Feedback_Submittedsop_id, feedback_type, suggestionFeedback frequency, improvement suggestionsAreopportunitiesAre technicians activelyproviding contributinguseful tofeedback? procedure improvements? WhatWhich aspects generateof mostwork feedback?Material_Usage_Reportedmaterial_id,orders quantity_used,need variance_from_planConsumption patterns, variance trendsAre material estimates accurate? Which procedures have high variance in material usage?improvement?

For System Admin

EventPropertiesMetricsInsightsSOP_System_Accessuser_id, role, feature_accessedUsage patterns, popular featuresWhich system features are most valuable to different user roles?Template_Import_Exportaction_type, template_count, user_idTemplate sharing, standardizationHow effectively is knowledge being shared across the organization?System_Performancepage_load_time, user_count, featurePerformance metrics, bottlenecksAre there performance issues affecting user productivity?Report_Generatedreport_type, filter_criteria, user_roleReporting patterns, data needsWhat information is most valuable to different stakeholders?