Manufacturer and Model Management (MX04US02)

1. Problem Statement

For Meter Manager:

- Repetitive manual entry of technical specifications for each new meter, leading to inefficient workflows

- Lack of standardized meter models resulting in inconsistent data entry and potential errors

- No centralized visibility into meter inventory across manufacturers, models, and conditions

- Difficulty tracking meter performance and condition trends across different models

- Inability to analyze procurement patterns and make data-driven vendor decisions

- Time-consuming process of managing individual meter records without bulk operations

For Meter Supervisor (Device Manager):

- Limited oversight of meter asset lifecycle and condition distribution

- Difficulty identifying optimal meter models for specific utility applications

- Lack of predictive insights for meter replacement planning

- No standardized approach to evaluate meter model performance across the fleet

Core Problem:

The current meter management system lacks a structured approach to meter model standardization and inventory oversight. This results in inefficient data entry processes, inconsistent meter specifications, limited visibility into fleet performance, and suboptimal procurement decisions due to lack of analytical insights.

2. Who Are the Users Facing the Problem?

Meter Manager:

- Oversees all metering operations and data collection

- Manages meter reading schedules aligned with billing cycles

- Coordinates meter installation, replacement, and maintenance programs

- Ensures data quality for consumption measurements

- Implements new metering technologies and reading methods

- Analyzes consumption data for system efficiency

Meter Supervisor (Device Manager):

- Manages the utility's meter inventory and specifications

- Oversees meter testing, calibration, and certification processes

- Coordinates large-scale meter replacement programs

- Evaluates new meter technologies for potential adoption

- Ensures meter compliance with industry standards and regulations

- Develops meter installation and maintenance procedures

3. Jobs To Be Done

For Meter Manager:

- When I need to add new meters to the system, But I have to manually enter repetitive technical specifications for each unit, Help me leverage pre-configured meter models with standardized specifications, So that I can reduce data entry time by 80% and eliminate specification errors.

- When I need to understand my current meter inventory distribution and performance, But I lack visibility into meter conditions and model performance across my fleet, Help me access comprehensive dashboard analytics showing inventory metrics by manufacturer, model, and condition, So that I can make informed decisions about procurement and replacement planning.

- When I need to evaluate which meter models are performing best in my system, But I don't have comparative analytics across different manufacturers and models, Help me analyze meter condition trends, failure rates, and performance metrics by model, So that I can optimize my procurement strategy and reduce maintenance costs.

For Meter Supervisor (Device Manager):

- When I need to create new meter model specifications for procurement, But I lack a standardized template system that captures all technical requirements, Help me define comprehensive meter models with all technical specifications and smart meter configurations, So that I can ensure consistent procurement standards and enable bulk meter additions.

- When I need to track individual meter lifecycle and condition changes, But I don't have visibility into meter age, installation history, and current status, Help me access detailed meter tracking with installation dates, age calculations, and condition monitoring, So that I can proactively manage meter replacement schedules and maintenance needs.

4. Solution

The Meter Inventory Management system provides a comprehensive solution for standardizing meter models and managing meter inventory:

Key Capability Areas:

- Inventory Dashboard

- Real-time metrics showing total manufacturers, models, and meters in system

- Visual breakdown of meter types (Smart, Photo, Manual) with counts

- Average meters per model calculation for distribution analysis

- Growth indicators showing new additions and quarterly trends

- Meter Model Management

- Standardized meter model creation with pre-configured templates

- Comprehensive technical specifications capture including dimensions, flow rates, and materials

- Smart meter configuration options for communication types and firmware versions

- Manufacturer and model name standardization with dropdown selections

- Technical Specifications Repository

- Complete technical parameter capture (dial length, count, max flow, connection size)

- Physical specifications including weight, dimensions, and materials

- Accuracy class definitions and IP rating configurations

- Smart meter features including OTA updates, encryption, and API integration capabilities

- Meter Condition Tracking

- Real-time condition monitoring with Normal, RCNT (Recent), and Faulty classifications

- Individual meter lifecycle tracking with installation dates and age calculations

- Device number assignment and status management

- Condition distribution analytics across all meter models

- Manufacturer and Model Analytics

- Manufacturer performance comparison across total meters and conditions

- Model-specific performance metrics and failure rate analysis

- Utility type distribution (Water, Gas, Electricity) across models

- Created by and creation date tracking for audit purposes

- Individual Meter Management

- Detailed meter records with device numbers and installation dates

- Age calculation in months from installation date

- Status tracking (Active, RCNT, Faulty) with visual indicators

- Action capabilities for viewing, editing, and managing individual meters

- Bulk Operations and Filtering

- Search functionality across model names and manufacturers

- Filter options by meter type, condition, and manufacturer

- Bulk meter addition based on pre-configured models

- Mass status updates and condition changes

- Smart Meter Configuration

- Communication type selection (cellular, RF, etc.)

- Firmware version tracking and update management

- Battery life specifications and monitoring

- Security features including encryption and API integration toggles

5. Major Steps Involved

For Meter Manager using the Meter Inventory Management feature:

- Access Inventory Dashboard

- Navigate to the Metering module in SMART360

- Select "Meter Inventory Management" from the navigation menu

- View dashboard showing 7 manufacturers, 7 models, 7,890 total meters, and 1,127 average meters per model

- Review growth indicators showing +2 new manufacturers this quarter and +3 models added this month

- Review Meter Model Distribution

- Examine meter type breakdown showing Smart (3), Photo (2), and Manual (2) models

- Use search bar to find specific models by manufacturer or model name

- Apply filters to view specific meter types or manufacturers

- Review table showing all models with their specifications and current inventory

- Analyze Meter Conditions

- Review condition distribution across models (Normal, RCNT, Faulty counts)

- Identify models with high faulty percentages for replacement prioritization

- Compare condition performance across different manufacturers

- Use condition data to inform procurement and maintenance decisions

- Access Individual Meter Details

- Click on a specific meter model (e.g., "E-Series Ultrasonic" by Badger)

- View comprehensive model information including technical specifications

- Review meter statistics showing 650 total meters with condition breakdown

- Access individual meter list showing 8 meters with their device numbers, installation dates, and current status

- Track Meter Performance

- Monitor individual meter age calculations (e.g., 28 months, 27 months)

- Review installation dates and track meter lifecycle progression

- Identify meters approaching replacement age or showing performance issues

- Use action buttons to view detailed meter information or make updates

For Meter Supervisor creating new meter models:

- Initiate Model Creation

- Click "Add New Meter Model" button from the inventory dashboard

- Access the meter model creation form with General Information and Technical Specifications sections

- Configure General Information

- Select manufacturer from dropdown or add new manufacturer using "+" button

- Enter model name in the required field

- Select meter type from dropdown (Smart, Photo, Manual)

- Enter optional make code for model identification

- Select supported utilities by checking Water, Electricity, and/or Gas checkboxes

- Enter Technical Specifications

- Input dial length in millimeters, dial count, and maximum flow rate (m³/h)

- Select connection size from dropdown and enter weight in kilograms

- Select accuracy class from dropdown options

- Enter physical dimensions: length, width, and height in millimeters

- Describe material composition in text field (e.g., "Brass body, polymer register")

- Select IP rating from dropdown for environmental protection classification

- Configure Smart Meter Features (if meter type is Smart)

- Select communication type from dropdown (cellular, RF, LoRaWAN, etc.)

- Enter firmware version information

- Specify battery life expectancy in years

- Toggle smart features: "Supports OTA Firmware Updates", "Encryption Enabled", "Enable API Integration"

- Save and Activate Model

- Review all entered specifications for accuracy

- Click "Save Meter Model" to create the standardized model

- New model becomes available for bulk meter additions and inventory management

- Model appears in inventory dashboard with initial zero meter count

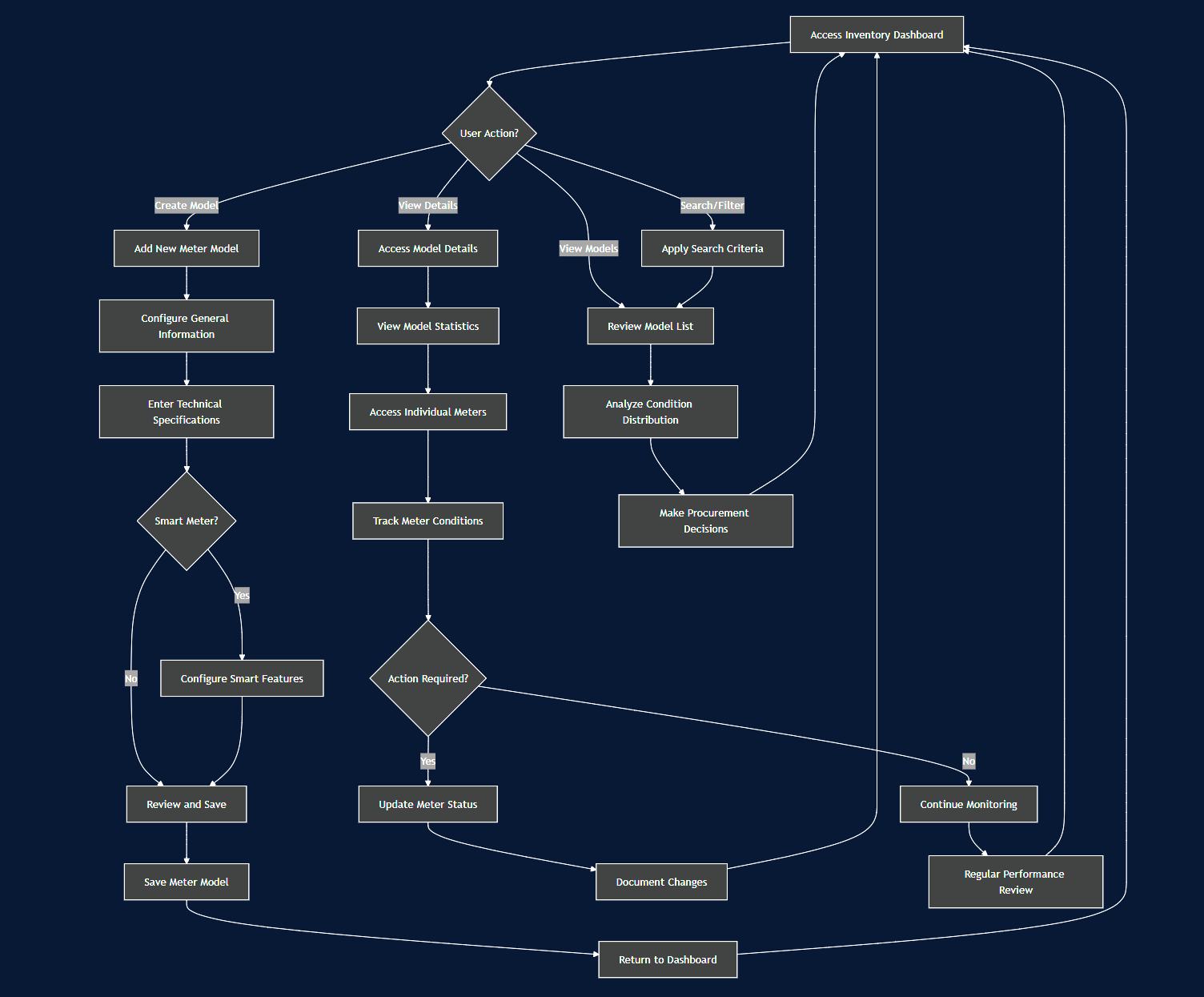

6. Flow Diagram

7. Business Rules

GeneralMain Rules:

- Dashboard Overview

AllPrimary heading identifying the inventory management system- Context for meter manufacturers, models, and specifications management

- Describes comprehensive inventory management capabilities

- Indicates system scope covering all meter-related data

- "To exit full screen, press 'Esc'" overlay message

- User guidance for interface navigation

- Indicates full-screen mode is currently active

- Blue primary action button with "+" icon

- Initiates new meter model creation workflow

- Primary call-to-action for expanding inventory

- Count of registered meter manufacturers in system

- Blue building icon represents manufacturer entities

- Growth Indicator: "+2 new this quarter" (green text)

- Shows recent expansion of manufacturer partnerships

- Count of configured meter models

mustacrosshaveallamanufacturers - Purple

uniquedatabasecombinationicon represents model catalog - Growth Indicator: "+3 added this month" (green text)

- Indicates active model expansion and system growth

- Complete inventory count of

manufacturerphysical meters in system - Green dial icon represents meter population

- Coverage Indicator: "Across all models" (green text)

- Shows comprehensive meter deployment across model types

- Mathematical average: Total Meters ÷ Total Models

- Orange speedometer icon represents efficiency metric

- Indicates distribution density and deployment patterns

- Free-text

systemsearch across meter models and manufacturers ManufacturerEnables quick location of specific inventory items- Supports partial matching and keyword searches

- Opens advanced filtering options for inventory view

- Funnel icon indicates filtering capabilities

- Enables complex queries and data segmentation

- Shows complete inventory regardless of meter type

- Total count of all configured meter models

- Default view providing comprehensive overview

- Filters to smart meters with IoT/communication capabilities

- WiFi icon indicates connected meter technology

- Count shows subset of technologically advanced meters

- Filters to meters using photo-based reading methods

- Camera icon indicates image capture functionality

- Count shows meters requiring visual reading verification

- Filters to traditional manually-read meters

- Clock icon indicates time-based manual reading process

- Count shows meters requiring field

istechnicianmandatoryvisits - Kamstrup

selected|fromSensusexisting|manufacturersElsteror|addedBadgeras|new Model name field is mandatory and cannot exceed 50 charactersNeptune- Meter

typemanufacturermustcompanybenames - Links

selectedto manufacturer-specific product portfolios - MULTICAL 603 | iPERL | V200 | E-Series Ultrasonic | T-10

- Specific product model identifiers from

predefined options: Smart, Photo, or Manualmanufacturers AtUniqueleastnamesoneforsupportedtechnicalutilityspecification and deployment- Smart (

Water,purpleElectricity,badgeGas)withmustWiFibeicon) - Manual

selected(blue badge with clock icon) - Photo (green badge with camera icon)

- Reading method classification for operational workflows

- 1,250 | 890 | 2,100 | 650 | 1,800

- Count of physical meters deployed for each model

CreatedInventorybyquantity tracking for maintenance andcreatedreplacement- Normal:

areOperationalautomaticallymeters in good condition (green badges) - RCNT: Recent installation or maintenance (yellow badges)

- Faulty: Meters requiring repair or replacement (red badges)

- Status breakdown with specific counts per condition type

- Water (blue badge) | Gas (gray badge)

- Service type classification for billing and operational purposes

- Determines rate structures and regulatory compliance requirements

- John Smith | Sarah Johnson | Mike Wilson | Emily Davis | Tom Anderson

- User identification for model configuration accountability

- Audit trail for inventory management changes

- 2024-01-15 | 2024-01-20 | 2024-02-05 | 2024-02-10 | 2024-01-25

- Date format: YYYY-MM-DD

- Chronological tracking of model addition to system

- Active (black badge for all entries)

- Operational status indicating model availability for deployment

- Controls whether model can be assigned to new installations

- View (eye icon): Opens detailed model information

- Edit (pencil icon): Modifies model configuration

- Delete (trash icon): Removes model from system

- Required field (marked with *)

- Dropdown populated with

currentregisteredusermanufacturers - Add Button (+): Creates new manufacturer if not listed

- Links model to specific manufacturer for organization

- Required field (marked with *)

- Text input for unique model identification

- Primary identifier for model selection and

timestampmanagement AllMake codeRequired fieldis(markedoptionalwith *)- Determines reading method and

limitedoperationaltoworkflow - Available

20options:charactersSmart, Photo, Manual - Optional manufacturer-specific product code

- Additional identifier for technical specifications

- Supports internal

referencemanufacturer numbering systems

Page Title: "Meter Inventory Management"

Subtitle: "Manage meter manufacturers, models, and specifications"

Full Screen Mode Notification

Action Buttons

Manage Manufacturers Button

Add New Meter Model Button

Summary Statistics Cards

Total Manufacturers: 7

Total Models: 7

Total Meters: 7,890

Avg Meters per Model: 1,127

Search and Filter Controls

Search Bar: "Search by model name withinor themanufacturer..."

Meter Type Tabs

All Meters (7)

Smart (3)

Photo (2)

Manual (2)

Inventory andData mustTable

Manufacturer beColumn

Model Name Column

Meter Type Column

Total Meters Column

Meter onConditions fieldsColumn

Utilities Column

Created By Column

Created On Column

Status Column

Actions Column

Add New Meter Model Form

General Information Section

Manufacturer Dropdown: "Select manufacturer"

Model Name Field: "Enter model name"

Meter Type Dropdown: "Select meter models default to Active status upon creationtype"

Make Code Field: "Optional make code"

Supported Utilities Checkboxes

- Required field (marked with *)

- Water: Water utility service support

- Electricity: Electric utility service support

- Gas: Gas utility service support

- Multiple selections allowed for multi-utility meters

Technical Specifications Rules:Section

Dial

lengthLengthmust(mm):be"0"- Numeric

enteredinput for meter dial measurement - Physical specification for installation compatibility

- Measured in millimeters

andforaccept only positive numeric valuesprecision

Dial

countCount:must"0"- Numeric

beinputa positive integer representing thefor number of dials onthemetermeterface - Reading complexity indicator for field operations

- Affects reading time and accuracy requirements

Max Flow (m³/h): "0"

- Maximum flow rate

mustspecification - Critical

beforenteredproper meter sizing and installation - Measured in

m³/h (cubic meters perhour) and accept decimal valueshour

Connection

sizeSizemustDropdown:be"Selectselected from standardsize"- Physical pipe connection specification

- Determines installation compatibility

- Standard sizes

(1/2",for3/4",utility1", 1.5", 2", etc.)connections

Weight

must(kg):be"0"- Meter

enteredweight specification in kilograms - Important for installation planning and

accept decimal values up to two decimal placeslogistics - Affects shipping and handling requirements

Accuracy

classDropdown:must"Selectbeaccuracy"- Measurement

selectedprecisionfromclassification - Regulatory

standardcomplianceclassificationsspecification - Determines billing accuracy and certification requirements

Length (

Classmm):A ±2%, Class B ±5%, etc.)"0"- Numeric

- Physical

dimensionsmeter(length,lengthwidth, height) must be entered in millimeters as positive integersdimension MaterialInstallationfieldspaceisrequirementfree text with a 200-character limitspecification- Critical for

describingmeter box and housing compatibility - Physical meter width dimension

- Installation space requirement specification

- Affects accessibility and maintenance clearances

- Physical meter height dimension

- Installation space requirement specification

- Determines mounting and housing requirements

- Free-text description of meter construction materials

- Important for environmental compatibility and durability

- Placeholder text provides format guidance

- Ingress Protection rating

mustforbeenvironmentalselectedresistance - Critical

fromforstandardoutdoor and harsh environment installations - Standard ratings (IP54, IP65, IP68, etc.)

defining environmental protection

Width (mm): "0"

Height (mm): "0"

Material Field: "e.g., Brass body, polymer register"

IP Rating Dropdown: "Select IP rating"

Smart Meter Configuration Rules:Section

Smart Meter Configuration section only appears(Appears when "Smart" meter type is

selectedselected)Communication

asType Dropdown: "Smart"Select communication type"- Wireless technology specification for smart meters

CommunicationOptions:typeWiFi,mustLoRa,beNB-IoT,selected from available options (Cellular, RF, LoRaWAN, Wi-Fi,GSM, etc.)- Determines connectivity and data transmission method

Firmware

versionVersionfieldField:accepts alphanumeric input up to 20 characters ("e.g.,"1.2.3",- Current firmware version identification

- Critical for compatibility and update management

- Version format guidance provided in placeholder

Battery Life (Years): "

v2.1.5")0"- Expected battery lifespan for wireless meters

BatteryMaintenancelifeplanningmustandbereplacemententeredscheduling- Measured in years

asforalong-termpositiveplanning

Smart

numberMeterwithFeatureoneTogglesSupports

decimalOTAplaceFirmwareprecisionUpdates Toggle- Checkbox indicating over-the-air update capability

SmartEnablesmeterremote firmware management- Critical for security patches and feature

togglesupdates

Encryption

(OTAEnabledUpdates,Toggle- Checkbox

Encryption,indicatingAPIdataIntegration)encryptiondefault to disabledcapability EnablingSecurity feature for data transmission protection- Compliance requirement for secure communications

Enable API Integration

requiresToggle- Checkbox

encryptionindicating API connectivity support - Enables third-party system integration

- Critical for data exchange and automation

Form Actions

- Discards all form inputs and returns to

bemainenabledinventory - Gray button providing exit option without saving

- Prevents accidental data loss with confirmation prompt

Save Meter Model Button

- Blue primary action button to commit new model configuration

- Validates all required fields before saving

- Creates new inventory item and returns to main dashboard

Model Detail View (E-Series Ultrasonic)

Header Information

Model Title: "E-Series Ultrasonic"

- Primary model identification

- Links to manufacturer (Badger) and type (Photo)

- Status indicator (Active) shows operational availability

- Returns to main inventory dashboard

- Preserves current filter and search state

Basic Information Panel

Manufacturer: "Badger"

- Manufacturer identification and branding

- Links to manufacturer-specific models and support

Model Name: "E-Series Ultrasonic"

- Complete model designation

- Primary identifier for

securityprocurementcomplianceand deployment

Make Code: "KC603"

- Manufacturer-specific product identifier

OTAAlternativefirmware update capability is recommendedreference for technical documentation

Meter Type: "Photo" (green badge)

- Reading method classification

- Camera icon indicates photo-based reading requirement

Created By: "John Smith"

- User accountability for model configuration

- Audit trail for inventory management

Created On: "2024-01-15"

- Model addition date to system

- Chronological tracking for inventory lifecycle

Utilities: "Water"

- Service type classification

- Determines billing integration and operational procedures

Technical Specifications Tab

Dial Length: "165 mm"

- Precise measurement for installation compatibility

- Critical dimension for meter housing selection

Dial Count: "8"

- Number of reading dials on meter face

- Affects reading complexity and time requirements

Max Flow: "3.5 m³/h"

- Maximum flow rate capacity

- Critical for proper sizing and installation applications

Connection Size: "3/4""

- Standard pipe connection specification

- Determines compatibility with existing infrastructure

Weight: "1.2 kg"

- Physical weight for shipping and installation planning

- Affects handling requirements and mounting considerations

Accuracy: "Class A (+2%)"

- Measurement precision classification

- Regulatory compliance and billing accuracy specification

Dimensions (L × W × H): "190 × 105 × 95 mm"

- Complete physical dimensions for installation planning

- Critical for meter box selection and space requirements

Material: "Brass body, polymer register"

- Construction material specification

- Important for environmental compatibility and longevity

IP Rating: "IP68"

- Environmental protection rating

- Indicates submersion and dust resistance capability

Meter Statistics Panel

Total Meters in System: 650

- Complete inventory count for this model

- Blue text indicates healthy inventory level

- Deployment scale indicator for maintenance planning

Meter Conditions Breakdown (of all

smartthe meter in the system of the selected model)Normal: 600

- Operational meters in good working condition

- Green indicator shows healthy fleet status

- Majority of deployed meters functioning properly

RCNT: 35

- Reading Canot be taken

- Yellow indicator shows transitional status

- Requires monitoring for stabilization

Faulty: 15

- Meters requiring repair or replacement

- Red indicator flags maintenance attention needed

- Small percentage indicates good overall reliability

Individual Meters List

Section Title: "Individual Meters (8)"

- Shows sample of deployed meters for

remote maintenance

Meter Statistics and Condition Rules:

Total meters in system is calculated as sum of all individual meters assigned to thethis model- Count indicates partial list view

- Detailed inventory tracking at individual meter level

- WM001234

Normal|(functioningWM001235properly),|RCNTWM001236(recently|flaggedWM001237 | WM001238 | WM001239 - Unique meter identification numbers

- Sequential numbering system for

attention),inventoryFaultytracking - DEV-KS-001234 | DEV-KS-001235 | DEV-KS-001236 | etc.

ConditionTechnicalcountsdevicemustidentifiers- Format:

equalDEV-[ManufacturertheCode]-[SequentialtotalNumber] - 2023-01-15 | 2023-01-20 | 2023-02-01 | 2023-02-10 | 2023-02-15 | 2023-03-01

- Date format: YYYY-MM-DD

- Chronological deployment tracking for

eachwarrantymodeland maintenance - 28 months | 28 months | 28 months | 27 months | 27 months | 27 months

- Calculated field showing meter age since installation

- Important for maintenance scheduling and replacement planning

- Active (green badge): Operational meters

- RCNT

+(yellow badge): Reading Cannot be Taken - Faulty

=(redTotal)badge): Meters requiring attention - Individual meter

ageconditionistracking - View

in(eyemonthsicon):fromOpensinstallationdetaileddateindividual meter information - Links to

currentmeter-specificdate Metermaintenancenumbers must follow utility naming convention (e.g., "WM001234" for water meters)Device numbers are unique identifiers assigned during meter installationhistory andcannot be duplicatedreadingsInstallationEnablesdatemeter-levelcannot be future datedmanagement andmusttroubleshootingMeterCreationstatus (Active, RCNT, Faulty) can be updated individually but must align with model condition counts

Individual Meter conditionsTable areColumns

Meter classifiedNo as:Column

Device (requiresNumber repair/replacement)Column

Installation metersDate countColumn

Age (NormalMonths) +Column

Status Column

Action calculatedColumn

Business beRules inand YYYY-MM-DDWorkflow

Model format

Dashboard Metrics Rules:Workflow

TotalGeneralmanufacturersInformation:count includes only manufacturers with at least one active meterBasic modelTotal models count includes all created models regardless of active/inactive statusTotal meters count is the sum of all individual meters across all models in the systemAverage meters per model is calculated as total meters divided by total models, rounded to nearest whole numberGrowth indicators (+2 new this quarter, +3 added this month) are based on model creation datesMeter type breakdown (Smart, Photo, Manual) counts models, not individual metersFilter counts update dynamically based on applied search and filter criteria

Access and Security Rules:

Only users with Meter Manager or Meter Supervisor roles can create or edit meter modelsIndividual meter details can be viewed by Meter Readers and Field Technicians for operational purposesBulk operations require Meter Manager role authorizationMeter model deletion is restricted if any individual meters are assigned to the modelHistorical meter data must be preserved even when models are archived or deactivatedAll meter model changes must be logged with useridentification andtimestampclassification- Technical Specifications: Physical and performance parameters

- Smart Configuration: Advanced features for

auditsmartpurposesmeters only - Validation: Required field verification and data consistency

- Deployment: Model activation and availability for assignments

DataInventory ValidationManagement Rules:Rules

AllModelsmandatorymust have unique names within manufacturer- Required fields must be completed before

metersaving - Smart meters require additional configuration parameters

- Meter conditions are tracked automatically based on status reports

- Individual meters inherit model

canspecificationsbeuponsaveddeployment NumericActive:fieldsModelmust validateavailable forappropriatenew installations- Inactive: Model deprecated but existing meters remain tracked

- Draft: Model under configuration, not yet deployable

- Manufacturer data

typelinks to supplier management - Model specifications integrate with installation planning

- Individual meter tracking connects to billing and

rangemaintenanceconstraints Dropdown selections must be from predefined valid options onlyText fields must not contain special characters that could cause system issuesDuplicate model names under the same manufacturer trigger validation errorTechnical specifications must be within realistic ranges for utility meterssystems- Smart meter configurations

mustenablepassIoTcompatibilityplatformvalidation before savingintegration

Status Management

Integration Points

8. Sample Data

Dashboard Metrics:

- Total Manufacturers: 7

- Total Models: 7

- Total Meters: 7,890

- Average Meters per Model: 1,127

- Growth Indicators: +2 new this quarter, +3 added this month

- Meter Type Distribution: Smart (3), Photo (2), Manual (2)

Meter Model Examples:

- Kamstrup MULTICAL 603

- Type: Smart

- Total Meters: 1,250

- Conditions: Normal (1,180), RCNT (45), Faulty (25)

- Utility: Water

- Created by: John Smith on 2024-01-15

- Status: Active

- Sensus iPERL

- Type: Smart

- Total Meters: 890

- Conditions: Normal (850), RCNT (30), Faulty (10)

- Utility: Water

- Created by: Sarah Johnson on 2024-01-20

- Status: Active

- Badger E-Series Ultrasonic

- Type: Photo

- Total Meters: 650

- Conditions: Normal (600), RCNT (35), Faulty (15)

- Utility: Water

- Created by: Emily Davis on 2024-02-10

- Status: Active

Technical Specifications Sample (E-Series Ultrasonic):

- Manufacturer: Badger

- Model Name: E-Series Ultrasonic

- Make Code: KC603

- Meter Type: Photo

- Dial Length: 165 mm

- Dial Count: 8

- Max Flow: 3.5 m³/h

- Connection Size: 3/4"

- Weight: 1.2 kg

- Accuracy: Class A (±2%)

- Dimensions: 190 × 105 × 95 mm

- Material: Brass body, polymer register

- IP Rating: IP68

Individual Meter Records (E-Series Ultrasonic model):

- Meter No: WM001234, Device: DEV-KS-001234, Installed: 2023-01-15, Age: 28 months, Status: Active

- Meter No: WM001235, Device: DEV-KS-001235, Installed: 2023-01-20, Age: 28 months, Status: Active

- Meter No: WM001236, Device: DEV-KS-001236, Installed: 2023-02-01, Age: 28 months, Status: RCNT

- Meter No: WM001237, Device: DEV-KS-001237, Installed: 2023-02-10, Age: 27 months, Status: Active

- Meter No: WM001238, Device: DEV-KS-001238, Installed: 2023-02-15, Age: 27 months, Status: Faulty

9. Acceptance Criteria

- The system must display accurate dashboard metrics showing total manufacturers, models, meters, and average meters per model

- The system must provide visual categorization of meter models by type (Smart, Photo, Manual) with accurate counts

- The system must support creating new meter models with all required general information fields

- The system must validate that manufacturer and model name combinations are unique within the system

- The system must require at least one supported utility selection (Water, Electricity, Gas) for each model

- The system must capture comprehensive technical specifications including dimensions, flow rates, and materials

- The system must show Smart Meter Configuration section only when meter type is selected as Smart

- The system must validate that all numeric fields accept appropriate data types and ranges

- The system must automatically populate created by and created on fields with current user and timestamp

- The system must display real-time meter condition statistics (Normal, RCNT, Faulty) for each model

- The system must calculate individual meter age in months from installation date to current date

- The system must provide search functionality across manufacturer and model names

- The system must support filtering by meter type, manufacturer, and condition status

- The system must display individual meter details including device numbers, installation dates, and current status

- The system must prevent deletion of meter models that have assigned individual meters

- The system must maintain accurate condition count totals that equal the sum of Normal + RCNT + Faulty meters

- The system must support bulk operations for managing multiple meter records

- The system must log all meter model changes with user identification and timestamp for audit purposes

- The system must validate smart meter configurations for compatibility before saving

- The system must display growth indicators showing new manufacturers and models added by time period

10. Process Changes

Current Process | New Process | Impact |

|---|---|---|

Manual entry of technical specifications for each individual meter added to system | Create standardized meter models once, then bulk assign meters based on pre-configured models | 80% reduction in data entry time; elimination of specification inconsistencies |

No visibility into meter inventory distribution across manufacturers and models | Comprehensive dashboard showing manufacturer, model, and condition analytics with real-time updates | 100% visibility into fleet composition enabling data-driven procurement decisions |

Reactive approach to meter replacement based on individual failure reports | Proactive replacement planning using condition analytics and age tracking across models | 40% improvement in planned vs. reactive maintenance ratio |

Limited ability to compare meter performance across different manufacturers | Detailed condition and performance tracking by manufacturer and model with comparative analytics | Enable vendor performance evaluation leading to 25% improvement in procurement ROI |

Manual tracking of individual meter installation dates and lifecycle information | Automated age calculation and lifecycle tracking with condition monitoring integration | Complete meter asset lifecycle visibility reducing manual tracking effort by 90% |

Inconsistent meter specifications leading to procurement and installation errors | Standardized technical specifications repository with validation rules | 95% reduction in specification-related errors and installation issues |

Time-consuming search for specific meter information across multiple systems | Unified search and filter capabilities across all meter models and individual units | 70% reduction in time spent locating meter information |

Limited insight into smart meter configuration and feature utilization | Comprehensive smart meter feature tracking with configuration management | Enable optimization of smart meter investments and feature utilization analysis |

11. Impact from Solving This Problem

Metric | Improvement Impact |

|---|---|

Data Entry Efficiency | 80% reduction in time required to add new meters through standardized model templates |

Specification Accuracy | 95% reduction in meter specification errors through validated model configurations |

Inventory Visibility | 100% real-time visibility into meter distribution by manufacturer, model, and condition |

Procurement Decision Quality | 60% improvement in vendor selection decisions through comparative performance analytics |

Maintenance Planning Efficiency | 40% shift from reactive to proactive maintenance through condition trend analysis |

Asset Lifecycle Management | 90% reduction in manual tracking effort through automated age calculation and condition monitoring |

Search and Information Access | 70% reduction in time spent locating specific meter information through unified search capabilities |

Compliance and Audit Readiness | 100% audit trail capability with automated logging of all model changes and meter assignments |

Smart Meter Optimization | 50% improvement in smart meter feature utilization through configuration tracking and management |

Overall Operational Efficiency | 45% improvement in meter management processes through standardization and automation |

12. User Behavior Tracking

Event | Properties | Metrics | Insights |

|---|---|---|---|

Dashboard_View | user_id, session_duration, metrics_viewed | Dashboard access frequency, Time spent reviewing metrics | How frequently are managers monitoring inventory metrics? |

Model_Create | user_id, manufacturer, meter_type, creation_duration, smart_features_enabled | Models created per period, Average creation time, Feature adoption rates | Which meter types and features are being standardized most? |

Model_Search | search_term, results_count, selected_model, user_id | Search effectiveness, Common search patterns | How are users finding specific meter models? |

Model_Filter | filter_type, filter_value, results_count, user_id | Filter usage patterns, Most common filter combinations | What criteria are most important for model selection? |

Model_View | model_id, user_id, view_duration, sections_accessed | Model popularity, Detail consumption patterns | Which models are being reviewed most frequently? |

Individual_Meter_Access | model_id, meter_count_viewed, condition_analysis, user_id | Individual meter tracking usage, Condition monitoring frequency | How deeply are managers analyzing individual meter performance? |

Condition_Analysis | model_id, condition_type_focused, analysis_duration, user_id | Condition monitoring patterns, Alert response times | Which condition types receive the most attention? |

Technical_Specs_Update | model_id, field_updated, old_value, new_value, user_id | Specification change frequency, Most updated fields | Which technical specifications require the most maintenance? |

Smart_Config_Enable | model_id, feature_enabled, user_id, timestamp | Smart feature adoption, Configuration trends | Which smart meter features are being utilized most? |

Bulk_Operations | operation_type, record_count, user_id, success_rate | Bulk operation usage, Efficiency gains | How effectively are bulk operations improving workflow efficiency? |

Performance_Compare | models_compared, comparison_duration, decision_outcome, user_id | Comparative analysis usage, Decision patterns | Which models are being compared for procurement decisions? |

Export_Data | export_type, model_selection, user_id, timestamp | Data export patterns, Reporting needs | What meter data is being shared outside the system? |

Questions answered by tracking:

- What is the correlation between meter model standardization and reduction in data entry errors?

- Which manufacturers and meter types are preferred based on model creation and usage patterns?

- How effectively are managers using condition analytics to drive maintenance decisions?

- What is the adoption rate of smart meter features and which configurations are most valuable?

- How does inventory visibility impact procurement timing and vendor negotiation outcomes?

- Which technical specifications require the most updates and why?

- What is the relationship between model complexity and user adoption rates?

- How are bulk operations improving operational efficiency across different user roles?

Wireframe

Wireframe: Link

Reference: Link